News from CCTV: Data show that in the first three quarters of this year, the national industrial robot production reached 595,000 units, which has exceeded the whole of last year, and the localization rate has also increased significantly. In 1982, the first domestic industrial robot was born in Liaoning. As the cradle of Chinese robots, the country's largest industrial robot production base has now been built there. Main station reporter Li Chengze is at the scene. We will connect with him immediately and ask him to introduce to you what new capabilities industrial robots have now?

Domestic industrial robots demonstrate the hard power of "intelligent manufacturing"

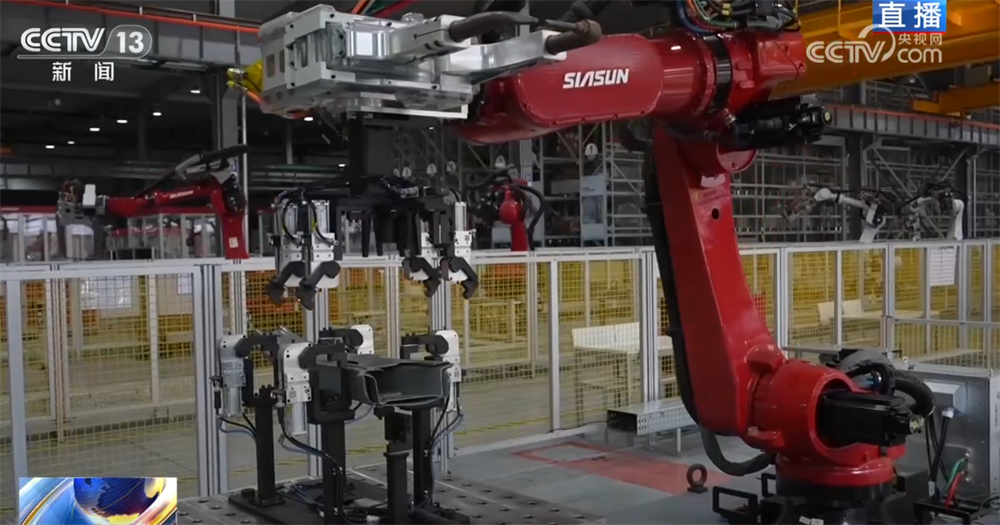

This is the Shenyang Xinsong Robot Pilot Workshop, known as the "base camp" of China's industrial robots, where "big training" of industrial robots is performed every day. Various robots ranging from 4 kg to 500 kg are put to the test in complex scenarios such as welding, palletizing, grinding and polishing.

Since this year, technicians have conquered the core control algorithm of the robot and independently developed advanced motion planning technology. This technology is like injecting "precision control secrets" into the robot, allowing it to "move smoothly and smoothly" during high-speed operation, while always maintaining the accuracy of "moving accurately and stopping steadily". At the same time, the company also released a dedicated software platform for "intelligent mobile robot system" and established a specialized research institute for embodied intelligence. A series of innovative achievements have been advanced step by step, injecting solid core competitiveness into domestic robots.

Industrial robots "add wings" to automobile manufacturing

Whether the technology is strong or not, it ultimately depends on the product. The industrial robot next to the reporter, newly launched this year, can be described as the perfect combination of "Hercules" and "Embroiderer". It has a wingspan of 2.7 meters and can grab a maximum weight of 270 kilograms. Its repeatable positioning accuracy reaches ±0.06 millimeters, which is equivalent to tens of thousands of continuous operations, and the error is no more than the diameter of a hair. Through structural strengthening, the overall rigidity is increased by 170%, and it only takes 2.2 seconds to weld a solder joint. This robot, with a localization rate of over 95%, is not only competent in traditional automobile manufacturing, but also more accurately meets the high-efficiency requirements of new energy vehicles for production lines. It has already received a large number of orders and has become a star product in smart factories.

Embodied intelligence brings robots to a new stage of practicality

If the robot just now is a "factory exclusive expert", another product developed by the company is evolving towards an "all-scenario all-rounder". The wheeled humanoid robot in front of the reporter is waving hello. It hides three "core magic weapons" - the wheeled "legs" design makes it more stable and flexible to move. The humanoid arms can cooperate to complete fine movements such as grabbing and sorting. The embodied intelligent "brain" it is equipped with can sense the environment in real time and make independent decisions. At present, this robot has the ability to be quickly implemented and can be used in warehousing logistics, new retail stores and other scenarios to efficiently complete tasks such as transportation and inventory counting.

"Made in China" robots shine on the global stage

True skills must ultimately withstand the test of the global market. Since the beginning of this year, the market performance of this company's robots, especially in overseas markets, has been very impressive. The export scale and quality of industrial robots and mobile robots have increased simultaneously, and they are exported to more than 40 countries around the world.

From electronics factories in Asia to automobile workshops in Europe, from warehousing centers in North America to manufacturing bases in Latin America, more and more "Made in China" robots are active in global production lines. Relying on excellent product quality and flexible performance to adapt to different working conditions, China's intelligent equipment is steadily entering the core stage of global high-end manufacturing, demonstrating the hard power of "China's Intelligent Manufacturing".