CCTV News: Jiangsu Province has a 954-kilometer coastline, rich marine resources, unique location advantages, and the development of the marine economy has also been the direction that Jiangsu has focused on in recent years. In Yancheng, Jiangsu, the coastal areas have also built their own wind power industrial parks and gradually transformed into a low-zero carbon industrial park. Many wind power companies gather here, and the production line is full of busy scenes. Wind power enterprises in coastal parks gather

There are many enterprises and production in the Sheyang Port Economic Development Zone of Yancheng, Jiangsu Province. Many roads here are named after enterprises, and many of them are private enterprises. In addition, the fan blade companies here are one by one, and the blades being shipped on the factory yard are neatly arranged, and you can occasionally encounter large trucks that transport blades on the road. The new energy green industry, especially the wind power industry, is accelerating its development. The blades over 100 meters are about to be shipped. The workshop is busy with production

This workshop is very big, and it is endless to see at a glance. Leaves over 100 meters are being manufactured here.

How are such a huge blade made? First of all, exclusive customized molds are needed. These two large and deep fiberglass parts are molds specially used to produce blades, and the deepest part is more than 2 meters. If you use this mold to fill it with water, you can fill it with about 300 tons.

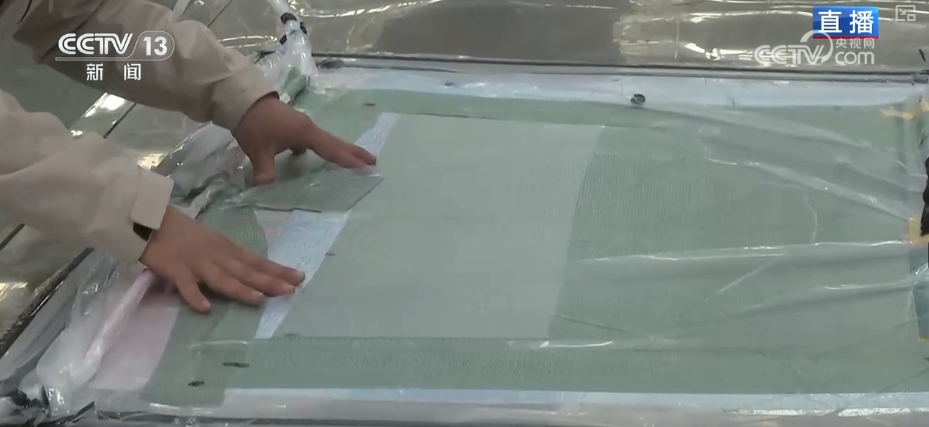

A guy like this needs wind and sun to expose outside. Is it made of metal? The answer is no. It is compacted by many layers of fiberglass cloth on the mold and then cured by adding epoxy resin to form the powerful muscles of the blade. From the side, the section of the blade is like a layered cake. Fiberglass cloth + epoxy resin How to form blades?

This is a 4-layer fiberglass cloth, then add epoxy resin, and after curing, it becomes this sheet. Its portion is relatively light, and its toughness is particularly strong. In fact, there are more than 50 layers of fiberglass cloth in the thickest part on the fan blades, and 4 layers are needed in the thinnest part. Compete for low carbon, gather chains and groups to work together to innovate

Now in the Sheyang Port Development Zone, 37 wind power companies have gathered to form a new energy industry chain. Almost all the raw materials needed for a wind power can be found here. At the same time, companies are also constantly innovating and developing, making their products more low-carbon and environmentally friendly.

Now, this company has produced recyclable environmentally friendly blades through joint research and development with other companies. Although the appearance of recyclable blades is no different from that of traditional blades, these blades can be easily separated by adding a special dissolving solution. This allows glass fiber cloth to be reused, and the main material of glass fiber blades accounts for more than 50%, which makes this production process more low-carbon and environmentally friendly.